Cladding and Additive Manufacturing with Copper

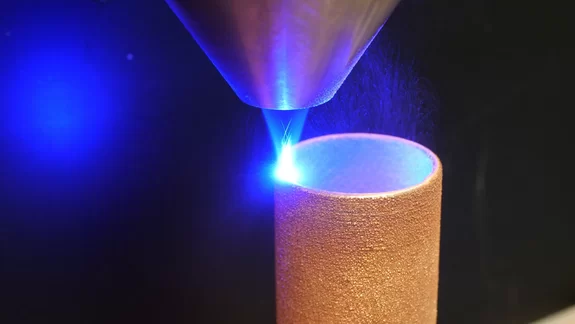

The blue laser enables copper deposition welding and the additive manufacturing of non-ferrous metals.

The blue laser enables copper deposition welding and the additive manufacturing of non-ferrous metals.

The blue laser was also able to convince in the first test runs of deposition welding with copper powder. In this process – also known as laser cladding – the blue laser beam creates a molten pool on the surface of the workpiece. With the aid of a powder nozzle, the copper is added at the same time so that it can be melted in the same beam. After a short cooling time, the workpiece and copper powder are now metallurgically bonded together. In addition, the welding process causes very little distortion and the coating is extremely durable. Here, too, the process is similar to that one of the laser in the infrared wave spectrum. Furthermore, the coating is electrically conductive due to the physical properties of copper.

The blue laser is particularly well suited for deposition welding or additive manufacturing with copper. The low energy absorption (lower than 10%) of highly reflective metals such as copper or gold in the wavelength range of 1,000 nm, proves to be a major challenge for standard IR lasers. The high initial intensities required, induce processes often characterized by turbulent melt pools and spatter formation, which are critical factors in the processing of electrical components.

Here, the blue laser achieves excellent results in copper processing because more than 50% absorption is achieved. We obtain an enormously calm process that does not require any additional power control. A powder efficiency of more than 80% can be achieved during the process, which is exceptionally good for copper-based components. Thus, even workpieces made of steel materials can be processed outstandingly with copper powder.

However, the blue laser is not limited to processing non-ferrous metals. Excellent results can also be achieved when processing other metals, such as steel or nickel.

Powder efficiency: >80%

Structure: Pure copper bulk material

Density: > 99.8%

Supported by DMG MORI Ultrasonic Lasertec GmbH

Which laser systems are particularly suitable for copper laser cladding and for processing gold and other non-ferrous metals? Here you will find a selection.