High Efficiency High Power Diode Laser

>52 % high efficiency diode laser for heat treatment applications like hardening, drying or curing

>52 % high efficiency diode laser for heat treatment applications like hardening, drying or curing

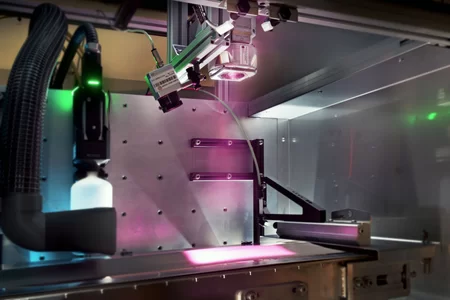

With the LDF product range, Laserline sets the standard for high-power diode lasers. The patented direct diode laser technology has proven itself over 25 years. The new high-efficiency laser, which offers a wall-plug efficiency of over 52 %, was developed on the basis of this technique. With its modular concept, the laser power is scalable between 15 and 30 kW and various processing optics can easily be exchanged, making the systems easy to service. Today, Laserline is the only manufacturer worldwide with long-term field experience with 20+ kW high power diode lasers.

Drying with diode lasers is a cost-efficient and environmentally friendly alternative to the widely used convective oven drying. The footprint for the laser-enabled heating system is about 50 % smaller than with conventional heating technologies. The drying process with diode laser needs no heating-up time and the temperature control is set by a closed-loop pyrometry system. With a wavelength of about 1 µm the highest absorption on carbon particles (as used in e.g. battery electrodes) is realized, while allowing in contrast to other photonic heating approaches a full transmission through dense water vapor. Ultra wide beams with more than 1 m offer a direct energy transfer into the substrate. The practically maintenance free diode technology minimizes down time and maximizes productivity in battery production processes.

The new Laserline OTX optics in combination with Laserline diode lasers are designed for the industrial heat treatment of large surfaces. Beam widths of over 1.5 meters can be achieved. The ultra-wide beam technology is successfully used in the roll-to-roll process for the electrode-drying of lithium-ion batteries.

| Laser Output Power (cw) | 15,000 W | 30,000 W | |||

|---|---|---|---|---|---|

| Model | LDF 15,000 DR | LDF 30,000 DR | |||

| Example intensity | 8.3 W/cm² @ 600x300 mm² | 3.1 W/cm² @ 1200x800 mm² | |||

| Compatible optics | OTX (fixed optics) or OTZ (zoom optics), Spot size tailored to customer design, e.g. 120 x 120 cm² | ||||

| Wall plug efficiency | > 52 % | ||||

| Fiber length | 20 m, other lengths on request | ||||

| Power stability | < +/- 2% over 2 hours | ||||

| Connectivity | Fieldbus interface, IoT Interface (OPC-UA) | ||||

| Additional optional components | Cross-guiding laser for precise positioning, power meter, future laser power upgrade package | ||||

Any questions on high efficiency diode lasers or surface treatment applications?

Please send us your request!