Laser Welding Plastic

Laser welding of plastics using diode lasers supplement traditional welding processes such as ultrasound, vibration, or hot plate welding.

To the examplesLaser welding of plastics using diode lasers supplement traditional welding processes such as ultrasound, vibration, or hot plate welding.

To the examplesLaser beam transmission welding always involves a component that is transparent for the laser and a laser absorbing component being merged. Before they are welded, the join partners are positioned and then pressed together. In the actual fusion process, the laser beam passes through the transparent component without significantly heating it up, before the absorbing component takes the laser energy, which heats up its surface. This energy is transferred via heat conduction onto the surface of the transparent component. The energy that has been absorbed plasticizes the plastic which, with pressure and heat conduction, leads to the components being joined. The existing joining pressure results in a substance-to-substance bond for both parts. The firmness of the resulting weld is typically within the region of the base material’s strength.

The diode laser has the edge compared to conventional solid-state lasers because of its wavelength spectrum and “top hat” steel profile without an intensity peak. In this way, local temperature peaks (which could damage the join partners) are avoided. Because of the diode laser’s local energy input, the plastic in the join zone is heated very quickly, without damage to the material, resulting in a homogeneous melt and zero fluff formation due to dry friction. Setting path monitoring systems, or temperature monitoring systems, can record the plastic welding process and pass the result to a higher-level control system. Functional changes to the component or new design ideas for the welding contour can be programmed flexibly. In particular, the laser protects interior and vibration-sensitive components or complex electrodes from damage by means of its contact-free heat input. The even energy distribution at the laser focus melts the welded joint without overheating the material, thereby preventing pores from being formed. The outstanding feature of thelaser is that it gives rise to much greater freedom of design in terms of the development of new components and housings. Plastic laser welding services make it possible to join plastic housings with inner electronic components (which are often damaged or dirtied by conventional methods such as vibration welding or ultrasonic welding) with a low thermal and mechanical impact and zero contact.

Diode lasers with low and medium laser power are ideal for high-quality and permanent joining of thermoplastic polymers using the transmission welding process. Various special optics and additional components such as pyrometers for temperature-controlled contour welding or CMOS cameras for process visualization can be adapted on a modular basis. For quasi-simultaneous welding, scanning systems with highly dynamic deflection mirrors guide the laser focus on any 2D contour.

In the dynamic landscape of battery technology, achieving robust hermetic sealing for pouch cells is paramount to ensure longevity and performance of each battery. The laser fusion of multilayer cover material comprising thermoplastic polymers and aluminum has emerged as a significant improvement, effectively preventing moisture diffusion into battery cells and extending their operational lifespan.

Traditionally, the industry has relied on conventional methods, such as hot bars or ultrasonic welding, for the thermoplastic melting of pouch battery cover foils. These direct contact processes are however lacking precision when it comes to large pouch cells, as large contact bar geometries are increasingly challenged by required precision at sealing temperature. Laserline introduces an innovative laser sealing technology that revolutionizes the production of pouch battery cells.

The utilization of laser technology enables direct heat generation within the multilayer foil. This advancement translates to a significant boost in production speed, surpassing conventional methods. Unlike hot bars, laser sealing eliminates limitations in sealing length and allows for flexible adjustment of width, offering unparalleled adaptability to diverse battery requirements.

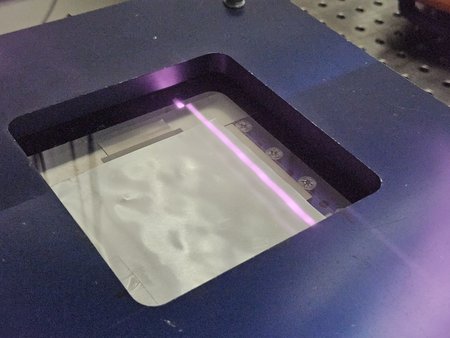

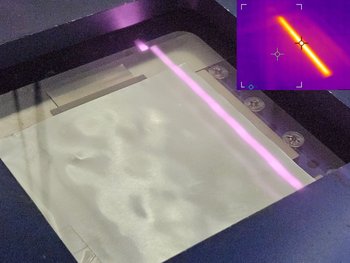

OTX Ultra Wide Spot Solution

This optic produces a long line that is particularly suitable for laser sealing of pouch cells.

More detailed information on the OTX optic can be found in the data sheet:

Lightweight automobile tailgates made from plastic are produced via transmission welding using Laserline’s diode lasers. Their unique feature: the weld seams for laser welding plastic are not visible, and post-processing in the inner visible area has become completely obsolete.

Which laser systems are particularly suitable for plastic welding? Here you will find a selection.

Then please do not hesitate to contact us!

Your Request