Blue lasers joining the fight against biofouling

In a series of tests, a new method for removing fouling from ship hulls and other underwater surfaces is currently being tested.

In the past, fouling on maritime surfaces was mainly treated with coatings and mechanical cleaning albeit with only moderate success. Environmental damage often had to be accepted, not to mention the damage to surfaces. A new process using Laserline’s blue diode lasers could now change all this. This is currently being tested in Helgoland.

Laser light against maritime fouling

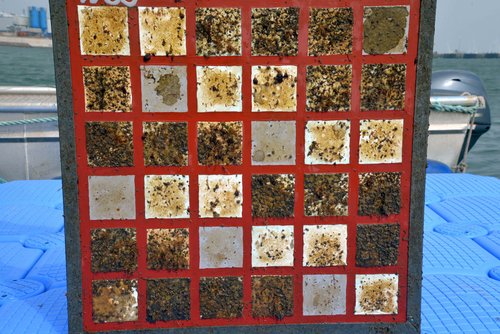

Blue laser light against maritime fouling? That sounds adventurous, and it is. Several dozen kilometers off the German coast on the North Sea island of Helgoland, a spectacular series of tests is currently being conducted. As part of a project called FoulLas, which is funded by the project coordinator Jülich* from the Federal Ministry of Economics and Energy (BMWi), Laserline, the Fraunhofer Institute for Manufacturing Engineering and Applied Materials Research (IFAM) and the Laser Center Hanover are tackling one of the biggest problems of maritime constructions: biofouling. Biofouling refers to the growth of algae, mussels and other marine organisms that are fairly well-known on ship hulls, harbor sheet pile walls or steel girders anchored under water. These often centimeter-thick and highly compacted fouling layers are critical especially in shipping traffic. On the one hand, they increase the weight and flow resistance, which means that a ship sails more slowly and consumes up to thirty percent more fuel. On the other hand, ships colonized by marine organisms are no longer allowed to berth at some ports for fear that foreign species may destabilize the local ecosystems. Particularly restrictive regulations in this regard have been issued by New Zealand and the US state of California, among others.

However, biofouling often causes considerable problems outside the shipping industry as well. For example, fouling can functionally impair tidal power plants, aquaculture cages or other movable constructions. In addition, marine organisms also attack anti-corrosion coatings and material structures of individual surfaces, thereby endangering even the long-term stability of purely stationary structures such as the foundations of oil rigs or wind turbines.

Biocidal & silicone-based antifouling coatings

Operators of ships and offshore facilities are therefore doing all they can to get rid of these unwanted guests or to ensure they do not settle in the first place. As a preventive measure, biocidal antifouling coatings have often been applied in the past, either to prevent the growth of vegetation from the ground up or to destroy the cell structures of adherent organisms. However, due to their toxic effect on other aquatic organisms, only a few biocides have been approved, and even these will completely be banned in the foreseeable future. A biocide-free alternative is silicone-based antifouling coatings. So-called silicone fouling release coatings (FRCs) create a particularly smooth surface structure. In addition, colonized surfaces are mechanically cleaned by diving teams at great expense and requiring plenty of time.

However, experience shows that these measures have only had limited success. Firstly, biocide and silicone coatings can only delay colonization due to the high biofouling growth pressure. The organisms colonize quickly and in large quantities so that even when coatings are used, a considerable amount of new biofouling growth can still be observed within a very short time. Secondly, mechanical cleaning by diving crews releases numerous marine organisms, which then migrate unwantedly into the local ecosystems; this is why mechanical ship cleaning is meanwhile forbidden in many ports or else a binding proof of fouling removal must be submitted before entry. Thirdly, it has barely been possible to clean colonized surfaces mechanically without damaging existing antifouling and anti-corrosion layers. The reason is that over millions of years, marine organisms, which at first glance appear unimposing, have developed highly effective strategies for adhering to surfaces — their attachment is almost as robust as industrial adhesive bindings. As a result, they can usually be removed only by force, leaving traces on the surface. Flaked areas or cracks in varnishes and silicone layers are not uncommon. This does not only promote the formation of rust spots, but also increases biofouling. This is because organisms such as barnacles can easily cling to cracks and scratches in surface coatings. Hence, a vicious circle!

New method: underwater irradiation by blue diode laser of Laserline

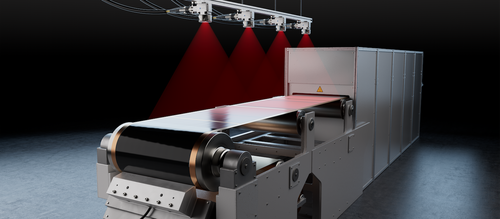

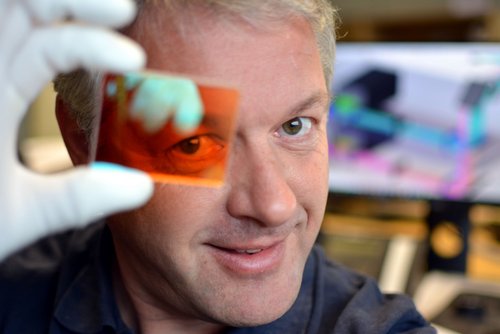

The Helgoland FoulLas project now addresses exactly this point. It is intended to come up with ways of removing the intractable fouling but in a manner that is gentle on the surface and ecosystem and thereby providing alternatives to the existing antifouling measures. The conventional mechanical removal shall be replaced by a treatment involving underwater irradiation by laser. The attempt here is to make use of the cell-damaging effect of the blue laser light of a Laserline diode laser. The aim is to damage the cell structures of the settled marine organisms to such an extent that the growth is washed away by the current. The corresponding experiments are carried out in the southern harbor of Helgoland, where the Fraunhofer IFAM operates a test facility for fouling tests. The project will run for several years so that it will be possible to monitor seasonal influences and thus develop seasonal strategies.

New approach in a real laboratory

If the new approach is proven effective in a real laboratory, a new cleaning process would be made available that would not only be more gentle and environment friendly, but also more efficient in removing marine organisms from ships. Not only will the time-consuming and cost-intensive mechanical cleaning phase be eliminated, but the cost of repair coatings will also be reduced. In addition, the simpler process design would make it possible to achieve shorter cleaning intervals, which would quickly pay for itself by reducing fuel consumption and emissions. Species migration would also be prevented, which would preserve local ecosystems and remove various restrictions on shipping’s choice of destination harbors. The first validated test results are expected to be made available as early as the autumn of 2020 or else no later than the middle of next year.

Read more about the blue diode laser!

If research projects are funded by the German federal or state ministry or by the EU Commission, the administrative implementation of this funding measure is often delegated to a so-called project coordinator. The project coordinator monitors the allocation and use of the approved funds and thus ensures that the public funds are used correctly. The project coordinator Jülich that was mentioned in the article, whose predecessor organization was founded in 1974 at the former Nuclear Research Centre Jülich (North Rhine-Westphalia, Germany), is one of the most important administrators of state funding in Germany with locations today in Rostock, Berlin and Bonn, in addition to its Jülich headquarters. According to information from the coordinator itself, project coordinator Jülich has so far supervised over 52,000 research projects on behalf of the federal government and managed funding of more than 20.6 billion euros.