Compact and brilliant

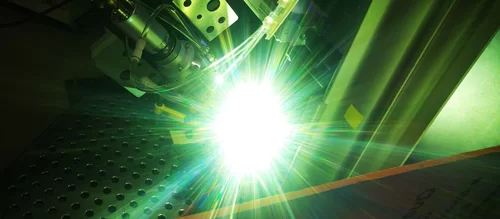

Multikilowatt lasers and highly compact design - for a long time this seemed to be incompatible. With the 19” diode laser modules of the Laserline LDM series, this has changed. The compact, lightweight modules are highly efficient, easily integrable, and can offer up to 6 kW output power at good focusability.

Compact class - most people know this expression. It means cars in the lower middle class that score despite limited space often with good equipment and high motor power. But “compact class for diode lasers”? This slogan about the Laserline LDM series surprises even though the associations it arouses are intended.

Because as with many cars in the compact class, LDM diode lasers also stand for the successful combination of little space and sophisticated advanced technology. Designed as a 19” rack mount module with 5 or 7 HE, they offer the user up to 6 kW output power. With 50 kg (5 HE) or 110 kg (7 HE), they are real lightweights as lasers in their power class, and their focusability is convincing, too: with the 6 kW laser, the beam quality is at 100 mm mrad, and with the 2.5 kW laser at even 30 mm mrad. Thus, they are approximately as focusable as solid-state lasers but have ten times as much socket output efficiency, with only a fraction of the necessary assembly space. In the end, LDM lasers rarely need more space than an office computer, can fit into every control cabinet, do not weigh much, and are highly efficient; however, they provide powers for which hitherto far bigger systems were necessary. So, you can call that actually a compact class.

But who actually needs this? The demand for highly compact laser solutions is everywhere, where the most diverse work pieces must be treated often in rapid change, and where appropriately lean and flexible processing systems are used, e.g. in job order hardening, cladding or additive manufacturing. In such process environments, lasers should be ideally installed in very narrow space and, for example, fitted in portable robots or even rotating systems. But in the past, those industry lasers were rarely available, and if they were available, their power spectrum was mostly insufficient especially for demanding metal processing. Therefore, whoever wanted to do welding applications or heat treatments often had to use laser systems with an equipment volume of several cubic meters. In some cases, that has led to compromises that were less satisfactory for the users.

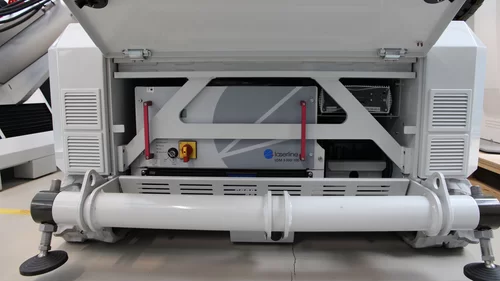

With the development of LDM diode lasers, these difficulties belong to the past. The lasers of this series can even find space underneath the conveyor belts of an interlinked production plant and can thus be fitted like compact cars into parking spaces. As parking aid, standard interfaces are available, and integration into existing systems thus succeeds without problems. Furthermore, LDM lasers have another advantage that you might also recall from the automobile compact class: the investment and operation costs are clearly lower than those for bigger models.

Given these plus points, it is no wonder that lasers of the LDM series can already be found in a whole bunch of industrial applications. To give but two examples: at the CladdOn System, developed by GTV Verschleißschutz GmbH, the slim, highly integrated cladding system contains, besides control and powder assembly station, a 6 kW LDM laser. The integration of an LDM device into a small mobile robot can be found at ALPHA LASER. A 3 kW LDM diode laser is here used for hardening and cladding, and can be moved flexibly with the help of a robot towards the workpiece.

Technically, the LDM series is tied to the concept of proven Laserline LDF diode lasers that provide up to 25 kW output power in mobile systems with less than one square meter of floor space. The concentration of all core elements within a narrow space, which is necessary for this design, is maximized at the LDM. In LDM modules besides the laser head and diode power supply, the control and heat exchanger are integrated. Furthermore, all these components are designed as modular components that even compress all maintenance procedures - here, the compact class of diode lasers can even hold their own vis-à-vis the car compact class.