From blue laser to high-power white light

LDMblue high-power diode lasers and rotating phosphor converters revolutionize the process of white light generation.

For a long time the generation of high-power white light reached technological limits when small light sources with high luminance were required. A new approach using blue diode lasers and rotating phosphor converters now makes luminous fluxes of over 100,000 lumens at a luminance of more than 1,000 cd/mm² possible.

New approach to generating high-power white light

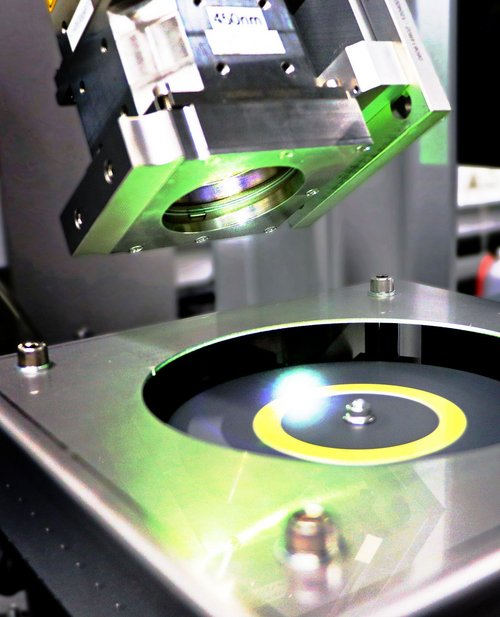

A blue laser illuminates a rotating disk to which a ring of phosphor has been applied - and dazzlingly bright light floods the room. What is being tested here in Laserline's application lab is a new approach generating high-power white light: To realize high luminous fluxes of over 100,000 lumens, a high-power diode laser with a wavelength of 450 nm "pumps" a so-called phosphor wheel. The blue laser light is largely absorbed by the phosphor converter, but a small portion is scattered and re-emitted at longer wavelengths. The result is a white broadband light spectrum. In continuous operation, 150,000 lumens can be achieved, and even 270,000 lumens for short periods, with luminance levels of up to 1,500 cd/mm². Such light output is required, for example, in solar simulation, i.e. for testing solar cells and photovoltaic systems using artificial sunlight. However, this option is also interesting for metrological applications or for event technology, especially for the creation of spectacular lighting effects for outdoor events.

Diode lasers in lighting technology - this brings back memories for technology experts, and indeed: before diode lasers were further developed into industrial lasers in the mid-1990s, they were already used to generate stage lighting effects. At first, however, even experts did not believe that the technology could do much more. The founders of Laserline, for example, had to ask themselves at their first trade show appearance what they wanted in the industrial environment "with this better flashlight”. It is now well known that this judgment proved to be wrong: The diode laser has long since a firm place in industrial material processing and is used for welding, hardening and coating steels and non-ferrous metals, but also in plastics processing, in semiconductor production and for drying printing inks. At first glance, it seems astonishing that it is now apparently returning to its beginnings and is being used in lighting technology again. However, this return is ultimately taking place under completely different circumstances. While no high-power diode lasers were available around two and a half decades ago, precisely such lasers are being used for this new application - the Laserline blue diode lasers, first diode lasers in the blue, visible light spectrum to achieve an output power in the multi-kilowatt range.

Small light sources with high luminace as a challenge

But how did this new approach appear? - In the past, luminous fluxes of over 100,000 lumens were generated for a long time using high-pressure discharge lamps. This technology, which is almost a century old in its basic features, combines high output with small light source sizes. But it has several disadvantages: The lamps are not very durable, their color rendering quality is mediocre, and their handling is fraught with hazards due to high pressure and ingredients that are sometimes harmful to health. An alternative came on the market in 1995: the first white-light LED with converter technology. In this solution, blue LED light was converted into broadband white light with the help of a cerium-doped YAG phosphor - colloquially known as a phosphor converter. Compared to the old high-pressure discharge lamps, this approach had several advantages: The LEDs scored with high energy efficiency and long service life, the broadband spectrum remained constant over the long term, and the luminous flux was flexibly scalable - from individual LEDs to complete LED modules. However, as soon as small light sources with high luminance were required, even this solution reached its limits: A high luminous flux could only ever be generated by using many LEDs placed next to each other. This limited the maximum achievable luminance and restricted the contrast effect of high-power lighting applications.

The use of high-power diode lasers

This is where the new approach using high-power blue diode lasers comes into play: for the first time, it’s possible to combine a very high luminous flux with a high luminance effectively and without any hazards in the application. The concept is based on the same physical principle that was already used for LEDs with converter technology - namely, converting blue light into white light via phosphor converters. However, while the LED solution and other previous laser concepts used individual emitters with an output power of around 3 to 5 watts and combined them to form complete systems with an output power of around 50 watts, the new approach uses many times this output power. After Laserline developed a new design concept for blue diode lasers in collaboration with technology partners from the semiconductor segment in recent years, the blue diode lasers are now available with an output power of up to 4,000 watts at a wavelength of 450 nm in continuous wave operation. As with infrared diode lasers, the new design concept uses high-density laser bars instead of combined individual emitters; the complete laser system can be easily integrated into a wide variety of application configurations.

Blue high-power diode laser "pumps" rotating phosphor converter

In order to make optimum use of these high output powers for white light generation, the established concept of phosphor conversion also had to be modified. The central challenge here was to distribute the much higher energy input of the blue high-power diode laser - compared to single emitters - as effectively as possible over a larger area and thus make maximum usage of the available power. The static converters used in the low-power range were no longer suitable for this purpose. As a solution, material manufacturers developed new phosphor shapes for a dynamic converter - the phosphor wheel mentioned at the beginning. Its wheel rotates at high speed during the conversion process. The laser spot, which is 15 to 20 mm² in size, irradiates each area of the phosphor ring only very briefly at a time. So that high laser power can be applied without overheating the converter and a correspondingly high light output can be generated. In addition to this optimized thermal management, the process also benefits significantly from the good focusing properties of the blue diode laser. With variable spot sizes and up to 20 mm-mrad beam quality it provides excellent conditions for precise adaptation of the irradiation to the phosphor converter. The optical conversion efficiency of the process is 230 to 300 lumens per watt of laser power, and continuously achieves high-power white light with a wavelength spectrum of 450 to 750 nm and high contrast in the test runs. The generated white light can be easily focused using compact optics. It can be scanned and so used for special exposures, for example. The size of the light source can be flexibly adjusted. The use of collimation optics ensures low divergence, and the emitted wavelength spectrum can be modified according to application requirements by selecting the appropriate phosphor converter.

Systematic combination

The systematic combination of the established phosphor conversion process with blue Laserline high-power diode lasers has ultimately resulted in a process that provides unprecedented possibilities for generating high-power white light with high luminance levels of more than 1,000 cd/mm2. The above-mentioned luminous fluxes of 150,000 lumens in continuous operation and 270,000 lumens in short-time operation - determined by 180° full-angle measurement - are only snapshots. In the test runs to date, only around 630 watts of maximum laser output power has been used in continuous operation. Meaning that not even half of the current power spectrum of blue diode lasers has been exploited. In the future, with improved thermal packaging, larger phosphor wheels and pulsed laser application, more than 200,000 lumens in continuous operation are considered realistic.