Laserline raises the power of blue CW diode lasers to 2 kW

LDMblue 2000-60 makes deeper and quicker non-ferrous metal weldings possible.

Within a year, Laserline has been able to double the power of blue CW high-power diode lasers with 450 nm wavelength. With the LDMblue 2000-60, a new high-power diode laser is available in the compact 19” rack, offering 2 kW output power at 60 mm mrad beam quality. As a result, when welding non-ferrous metals, especially when joining copper components for the electronics industry, higher process speeds and deeper weldings become possible.

Mülheim-Kärlich, Germany, 27.04.2020 – Laserline, the international leading developer and manufacturer of diode lasers for industrial material processing, consistently thrives on the development of its blue CW high-power diode lasers with 450 nm wavelength. After the worldwide first blue CW diode laser with up to 1 kW output power was presented less than a year ago, now already twice the power could be attained. The Laserline LDMblue 2000-60 offers 2 kW output power at 60 mm mrad beam quality and thus opens up a whole new range of possibilities for the joining of non-ferrous metals, especially copper. Due to the increased power, higher feed rates have become possible for example, which reduces critical energy inputs into the component and thus brings decisive advantages, especially at the production of battery cells irrespective of whether they be pouch cells or cells with cylindrical or prism shape.

Significant process optimizations can also be achieved at deep weldings of bigger conductor cross-sections. Hitherto, such deep weldings were only possible using hybrid systems that combined blue and infrared diode lasers. Without infrared support from the 1 kW blue laser beam, only welding penetration depths of 0.6 to 0.7 are viable. Because of the power increase to 2 kW, deep weldings can now, to some extent, be made solely with blue diode lasers. In welding processes that continue to require hybrid systems, additionally clear efficiency advantages can be gained with the LDMblue 2000-60. Because of the power increase of 1 kW, the infrared energy needed in the hybrid process can be reduced by about 2 to 3 kW, which leads to a sustainable reduction of the operation costs.

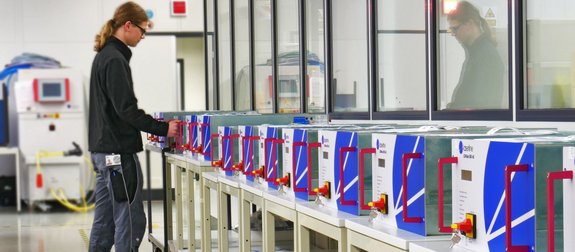

Thanks to the compact LDM design for the 19‘‘ rack, even the new LDMblue 2000-60 lasers can easily be integrated in a space-saving manner into all common production plants. Currently, the new laser systems are only available in the Laserline application laboratories for tests. Additionally, pilot devices are delivered to selected customers. You can find detailed information about the Laserline LDMblue series online at www.laserline.com/ldm-blue.