Press Release: Laserline at the Battery Show 2023

Laserline to exhibit energy-efficient applications for e-mobility

Economic series manufacturing of batteries, e-motors and brake disc claddings

At the Battery Show 2023 Laserline will present energy-efficient solutions for industrial material processing in the field of electromobility. Key topics include copper welding with blue 3 kW cw diode lasers, brake disc cladding to reduce urban particulate pollution, laser drying processes for economical series manufacturing of lithium-ion batteries, and welding applications for sealing battery casings.

Mülheim-Kärlich, April 4, 2023 – Diode laser specialist Laserline will be presenting its portfolio of solutions for economic series manufacturing of batteries, electric motors and brake disc coatings at Battery Show 2023 (May 23-25 in Stuttgart, Hall 8, Booth E81). Among the highlights of the trade show presentation is the world's first blue diode laser with 3 kW cw output power, which has been developed in particular for the processing of copper components – for example as used in electrical drive technology or for power electronics. This industrial laser represents the highest currently available power class in the blue wavelength spectrum around 445 nm, a wavelength which is more effectively absorbed by non-ferrous metals than infrared radiation. Among other aspects, blue lasers enable near-surface heat conduction welding of thin copper components and offer two decisive advantages over competing approaches that utilize green laser light: Firstly, direct light generation using laser diodes eliminates the need for complex and efficiency-reducing frequency conversion. Secondly, the laser systems exhibit a significantly smaller footprint, which enables straightforward system integration. And up to cw output powers of 2 kW, the blue lasers are even available in a compact 19" rack format, making integration still easier.

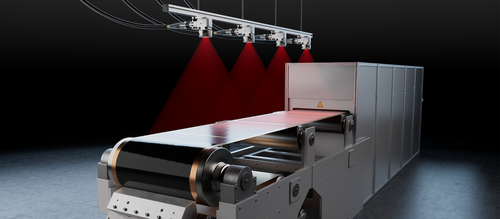

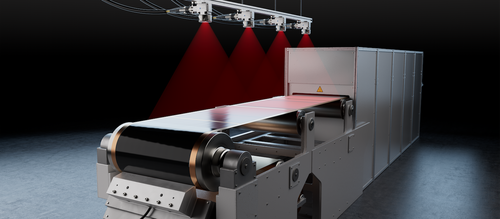

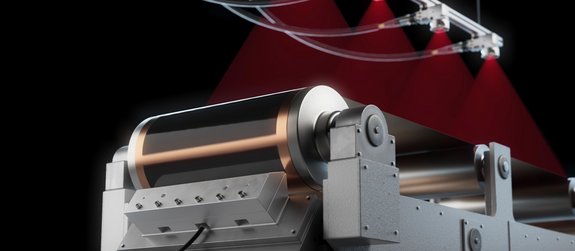

Another focus of the trade show exhibit is a laser drying process for low-emission and cost-effective series manufacturing of lithium-ion batteries. It was developed as part of the IDEEL research project (Implementation of Laser Drying Processes for Economical & Ecological Lithium-Ion Battery Production) – under the leadership of Laserline – and enables the production of laser-dried anodes and cathodes in a roll-to-roll process for the first time. In this process, the diode laser supplements or replaces the market-dominating convective drying process and reduces the total energy requirement for drying by more than 25 percent, while at the same time enabling a reduction in necessary production area. When considering circuit loads of over 1,000 kW for a conventional GigaFab drying line, this makes significant CO2 savings achievable and thus represents an energy turnaround for this type of production process.

Laserline is also presenting a high-speed, series mature process suitable for cost-effective hard coating of brake discs. This process enables the realization of very thin yet wear-resistant claddings that combine long-term corrosion and abrasion protection. These types of cladding reduce the amount of the environmentally and health-hazardous PM10 particulate matter (up to 10 µm) generated through braking by up to 90 percent. This also ensures compliance with the requirements of the upcoming Euro 7 vehicle emission standard, which is due to come into force in 2025 and for the first time sets specific limits for particulate emissions from braking systems.

As a further highlight, Laserline will be showing diode laser-based welding solutions for sealing battery casings. Both hot wire and spot-in-spot module optic applications will be presented here, the latter describing a narrowly focused internal spot that is overlaid by a larger rectangular spot. Compared to conventional processes such as MSG or MIG welding, both approaches promise higher process speeds, improved gap bridging ability and durable welds of excellent quality.