Wear Protection for Agricultural Machinery Knives

Agricultural knives are exposed to heavy stresses when working in the field, and signs of wear appear therefore quickly. To increase service life of cutting tools, laser coatings are therefore being implemented more and more frequently. With success: The thin, highly stable carbide coatings effectively protect the knives from abrasion, bumps and shocks, thus significantly extending their tool life. No wonder that demand is increasing.

Diode Lasers in Agriculture?

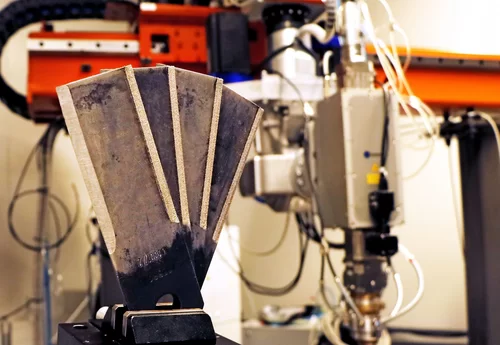

What seems strange at first has long since become reality. Of course, the laser does not work on the field - that would not make any sense. But it does treat the tools that are used to process the field and crops. Today, baler knives, loader wagon knives, forage mixer wagon knives, digging knives, forage harvester knives, and even chopping shares are often coated by laser cladding- with the intention of protecting them from premature wear. The service life is increasing, and thus the interest in this coating technology.

Thin Layers with High Stability

Coated agricultural knives are not a brand new innovation: The service life of knives has already been increased in the past by using wear protection coatings. However, the thermal spray and arc welding processes used for this purpose have disadvantages in terms of efficiency and energy input. Thermal spray coatings, for example, are comparatively costly to implement due to the necessary pre- and post-processing steps. Arc welding, on the other hand, generates such high energy inputs that there is a risk of deformation of the component, especially along the cut edges. In addition to that, very thin layers can only be realized with limited accuracy, which also has a negative effect on blade areas.

The Effort

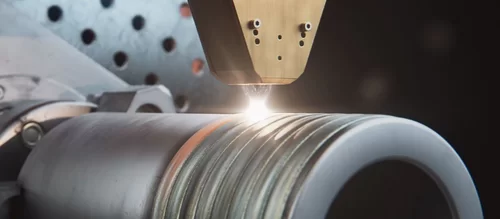

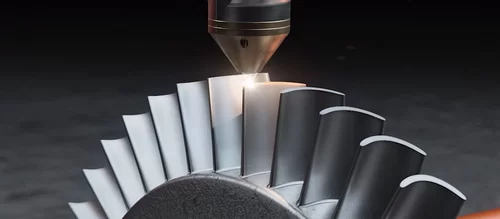

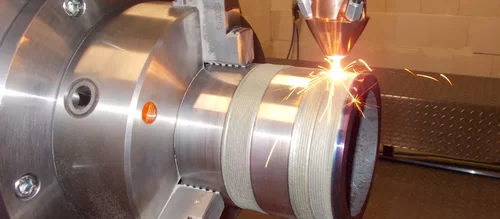

Laser buildup welding, on the other hand, has none of these disadvantages. The effort required for preparation and post-processing is very low, and the process is easy to implement. Here, the laser serves as a heat source: It creates a molten pool on the surface of the blade into which the coating material is applied as powder or wire - usually a hard metal such as tungsten carbide. The energy input of the diode laser is short, intense and very consistent due to the homogeneous beam profile. Furthermore, the output power can be regulated very precisely within milliseconds. This ensures accurate molten pools with low degrees of dilution and keeps the thermal load low - especially in the sensitive, filigree blade area. There is hardly any risk of contamination or deformation. The coatings produced are fusion-metallurgically bonded to the blade surface and are therefore very stable so that they can withstand even hard blows and bumps. Thanks to the excellent process control, it is also possible to produce very fine and precise coatings with a high degree of stability. It provides full functionality along the cutting edges. The overall service life of the knives is thus significantly increased.

Double Service Life in Practical Use

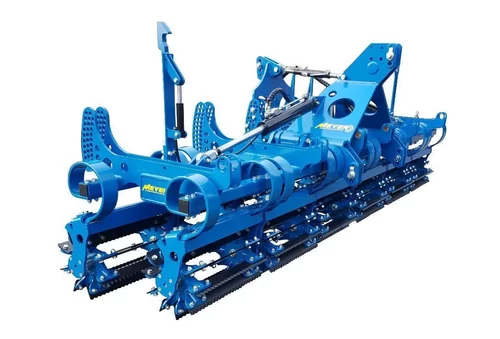

The advantages of laser-coated agricultural machinery knives are exemplified by a knife roller from Meyer Agrartechnik equipped with Jäkel's JADU®-Stratum reversible knives. The knives feature wave-shaped blades on both long sides and are coated with a diode laser-based carbide coating on the rear side. The front side, however, which comes into contact with the soil or plants, remains uncoated. This coating approach leads to a self-sharpening effect: During field work, the softer base material on the front side is abrasively removed, while the harder coating on the back side remains and becomes the blade. The service life is accordingly more than doubled, and the quite higher acquisition costs are quickly amortized.

Coating Approach

The one-sided coating approach chosen by Jäkel is, of course, only one of several coating options that are realizable by laser buildup welding. However, it always makes it clear why the demand for laser-coated knives is increasing: The results are convincing, and new opportunities are being opened up that did not exist before. Diode lasers in agriculture - what seems strange promises to be a success story, and the writing has only just begun.

Read more about Laser Cladding.