Sustainability

The sustainable use of resources is an important concern for Laserline.

Sustainable laser applicationsThe sustainable use of resources is an important concern for Laserline.

Sustainable laser applicationsThe sustainable use of resources is an important concern for Laserline. We attach great importance to this as early as the product development stage, so that the use of energy and natural resources can be optimized. In our supply chain and production, we strive to constantly improve our environmental impact.

Not only our company itself, but also our products and the applications they enable are designed to be sustainable. Compared to other laser types, such as fiber or disk lasers, the diode laser is the most energy-efficient laser of over 50 % efficiency. No other laser has a comparable electrical efficiency. If a diode laser is operated with renewable energies in the future, it can replace a large number of thermal processes, such as drying or heating, which are currently generated by gas or other fossil media, in a climate-neutral way. This is comparable to a heat pump replacing a gas or oil heating system.

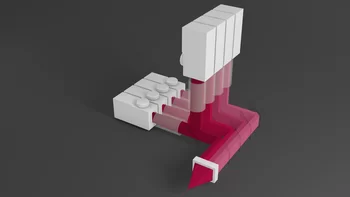

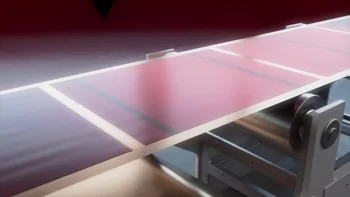

One application relevant to Laserline's growth is heating and drying using large-area laser spots. With the help of our products, our customers are able to save up to 85% energy when drying battery foils in battery production for electric vehicles, for example.

We also support sustainable and future-oriented applications with our equipment and expertise. This includes, for example, the laser cladding of brake disks with the aim of reducing the fine dust pollution caused by vehicle brakes, which account for up to 30% of the total fine dust generated by a car.

We are also replacing conventional manufacturing processes such as centrifugal casting with more resource- and energy-efficient laser coating, for example in cladding of bearings for wind turbines. But we also achieve high levels of efficiency and CO₂ savings in established applications such as welding aluminum doors, battery modules or electric motor components.

A management system in accordance with DIN EN ISO 14001:2015 was introduced in order to anchor our approach to the conscious use of environmental resources even more firmly. This covers the entire company, which is regularly audited for optimization potential.

If you have any further questions about our environmental policy, please contact quality@laserline.com directly.

Please feel free to contact us!

Your Request